A material’s yield point occurs when it switches from elastic behaviour (where releasing the applied force returns the material to its original shape) to plastic behaviour (where deformation is permanent). In materials science and engineering, the yield point is a point on a stress-strain curve that denotes the end of the elastic limit and the start of plastic behaviour.

Engineers can use the yield point to calculate yield strength and yield stress.

The yield strength of a material is the most significant force that it can endure without sustaining irreversible damage.

Similarly, the yield stress determines how far the material may bend before irreversible damage occurs.

The yield point is also the transition point in material deformation from atomic bond stretching to dislocation motion. Beyond the yield point, the atoms have stretched to their limit, and additional deformation occurs when atoms pass one other.

When you pull a material, the atomic bonds stretch and cause it to expand. When the stress is removed (below the yield point), the atomic bonds relax and the material returns to its original form. However, the bonds have achieved their maximal stretchiness at some time. The bonds must now be broken.

Table of Contents

Yield Point in Simple Terms

In material testing, the yield point is a concept that refers to the stress level at which a material begins to deform plastically, rather than elastically. The yield point is an important factor in determining the strength and ductility of a material. It is the point at which the stress-strain curve of material changes from a linear elastic region to a plastic region. The yield stress is the stress value at the yield point, and the yield strain is the corresponding strain value. The yield point can be determined experimentally by performing a tensile test on a sample of the material.

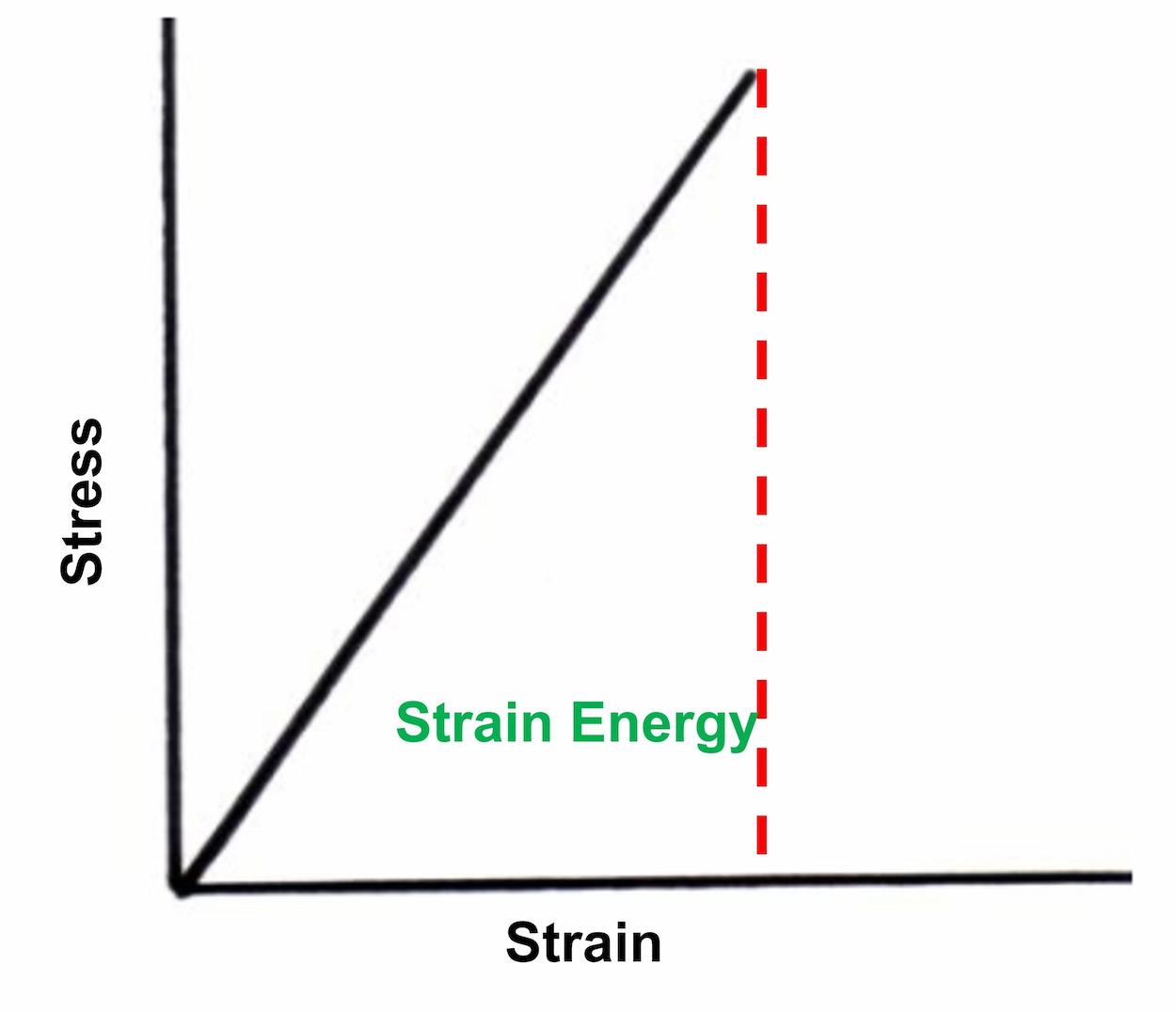

Stress-Strain Curve and Yield Point

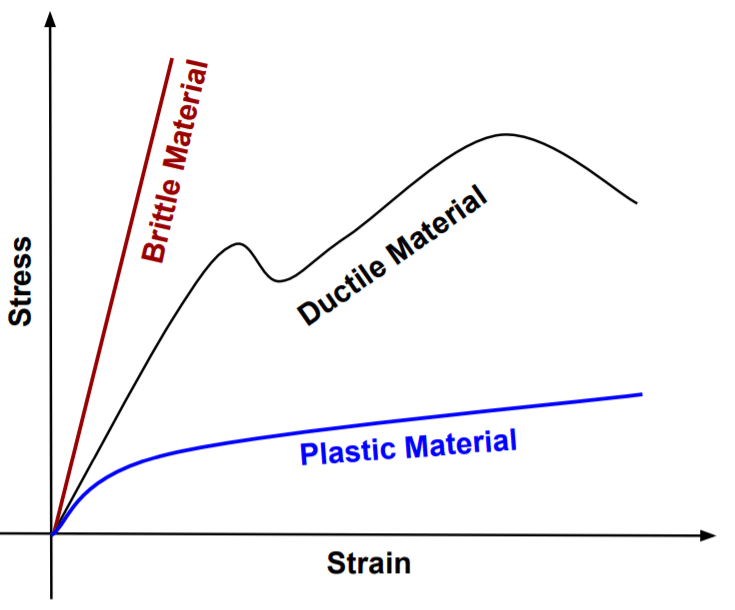

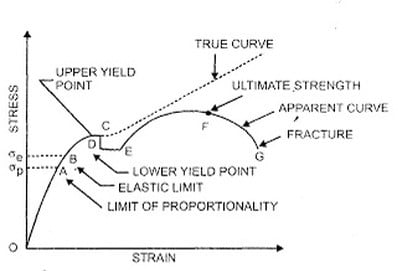

The stress-strain curve is the most significant diagram for mechanical characteristics. This curve links force (stress) to the amount of movement of a material (strain). Hooke’s law applies to the straight-line section of the stress-strain curve in the elastic regime. In the elastic regime, every deformation is 100 per cent recoverable. After the elastic limit, the material “yields” permanently. This is the plastic regime, and the distortion is not totally reversible when a material is deformed into it. The shift from the elastic to the plastic phase is not always obvious.

Draw a line parallel to young’s modulus to identify the yield point on the stress-strain curve (the slope of the straight-line portion). Move this line to the right until it intersects the stress-strain curve at 0.2 per cent strain–the yield point is where this line intersects the stress-strain curve.

The yield stress or yield strength is the y-axis value at the yield point, and the yield stress is the x-axis value at the yield point.

Yield Point of Ductile Metals

In-ductile metals, there may be two yield points on the stress-strain curve. The first yield point is the upper yield point. After this point, the stress drops. Then there is the lower yield point after which stress can increase again.

Yield Point of Brittle Materials

Brittle materials do not show plastic behaviour, hence on the stress-strain curve, the breaking point of ultimate tensile stress occurs directly after the elastic limit ends. Brittle materials have yield stress equivalent to ultimate tensile stress.

Important Definitions

- Ultimate strength: The point that separates the strain-hardening region and the necking region

- Limit of proportionality: In a stress-strain curve the area where the specimen material acts like a spring and any strain caused is completely reversible.

- Fracture point: The point where the strain reaches its maximum value and the material actually fractures

Significance of Yield Point

The yield point is a critical point in the stress-strain behaviour of a material, and it is an important factor in the design and analysis of structures. It is the point at which a material begins to deform plastically, meaning that the deformation is permanent and does not disappear when the applied stress is removed.

In engineering, the yield point is used to determine the strength of a material and the amount of stress that it can withstand before undergoing permanent deformation. This information is critical for determining the safety margins of a structure and ensuring that it can withstand expected loads and stress conditions.

Additionally, the yield point is also used to classify materials into different strength categories and to compare the performance of different materials. For example, materials with a higher yield point are generally considered to be stronger and more durable than those with a lower yield point.

Overall, the yield point is a crucial concept in the field of materials science and engineering, and it is used to ensure the safety and reliability of structures in a wide range of applications.

Summary

- The yield point is the point at which a material changes from elastic to plastic.

- In-ductile metals, there may be two yield points on the stress-strain curve.

- Brittle materials have yield stress equivalent to ultimate tensile stress

Related Topics

Stress in Physics| Definition and Easy Examples

Strain Energy Concept And Formula Derivation

Flexural Strength- An Overview

The Spring Constant & Spring Force Concept

Elastic Potential Energy| Definition, Formula, and Examples

What Is Malleability in Metal?

Frequently Asked Questions

1. What is resilience?

The capacity of a material to endure elastic deformation without plastic deformation is referred to as its resilience. The modulus of resilience is the greatest amount of volume that material may elastically deform before being permanently distorted.

2. Define plastic deformation?

Plastic deformation is the permanent distortion that happens when tensile, compressive, bending, or torsion loads surpass the yield strength of a material, causing it to elongate, compress, buckle, bend, or twist.

3. Explain elastic deformation?

Elastic deformation is a temporary deformation of a material’s shape that is self-reversible once the force or load is removed. Elastic deformation occurs when a material’s shape is altered by applying a force within its elastic limit.

4. What is the Yield point?

In mechanical engineering, the yield point is the load at which a stretched solid material begins to flow or change shape permanently, divided by its original cross-sectional area; or the amount of stress in a solid at the commencement of permanent deformation.

4. Is the tension and stress the same in physics?

Tensile stress (also known as tension) is a type of stress that causes a material’s length to grow in the tensile direction. The material’s volume remains constant. When two equal and opposite forces are applied to a body, the resulting tension is known as tensile stress.

5. What is an angular displacement?

The shortest angle between the starting and end locations of an item travelling in a circular motion around a fixed point is defined as angular displacement. Because angular displacement is a vector quantity, it has a size and a direction associated with it.

6. Briefly define conduction in physics.

Conduction in physics refers to the transfer of energy via the movement of particles in contact with one another.

7. What are quarks?

In physics, quarks are the fundamental building units of matter. They’re most typically found within protons and neutrons, the essential components of the universe’s atoms. Based on present experimental findings, quarks appear to be really basic particles that cannot be further subdivided.

8. Define uniform circular motion?

Uniform circular motion is defined as the constant-speed motion of an object in a circle. An object in uniform circular motion moves at a constant speed.

More Interesting Topics

Fatigue Testing of Thermoset Composites

Gamma Decay| Radioactive Decay

Kinetic Energy Formula

Quarks in Physics

Angular Momentum| Rotational Momentum

Dynamic Viscosity-An Overview

Conduction in Physics| Easy Examples

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023