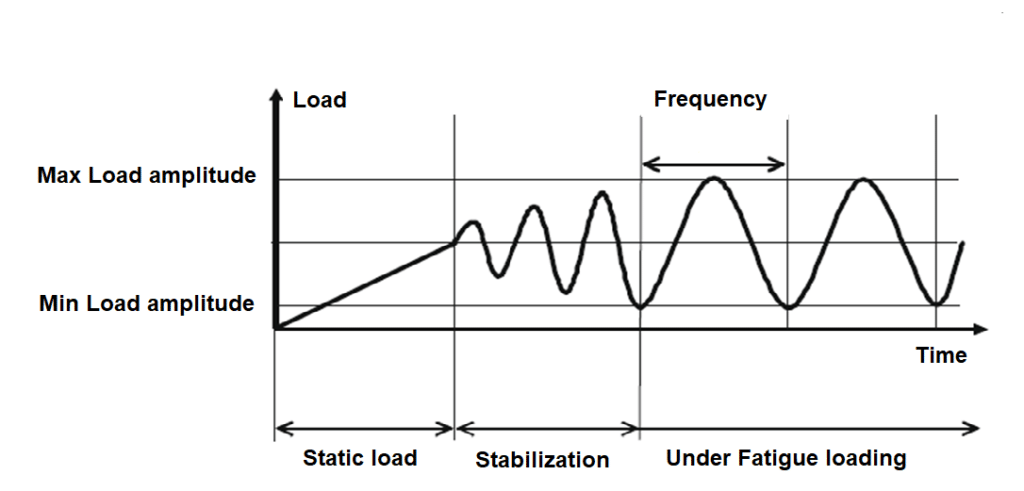

Fatigue testing of thermoset composites involves putting cyclic force into a thermoset composite coupon. These tests are used to find crack development data, identify key areas, or show the safety of fatigue-prone areas.

In technical terms, fatigue testing is the measure of structural damage as a result of repetitive loads that are less than the ultimate tensile strength and possibly yield strength.

Fatigue failure in polymers can occur in two ways:

- thermal failure owing to softening and melting caused by hysteretic heating

- mechanical failure caused by fracture initiation and propagation.

Table of Contents

Why we need to know Fatigue Life

Fatigue life calculation is important to design a product.

For instance, The fatigue life of aerodynamic structures is significantly influenced by stress concentration zones. Microcracking in these areas can cause a catastrophic collapse of the overall structure in a very small number of cycles.

As a result, it is critical to find endurance stress so that while designing a structure we could keep design stress far within the material’s endurance limitations.

Fatigue Testing of a Material in Simple Words

Fatigue testing of materials is a way to assess how a material will perform when subjected to repeated stress over time. During fatigue testing, the material is subjected to cyclical stress, such as bending or stretching, and the number of cycles it can withstand before failing is measured. This information is important for engineers and designers because materials can fail unexpectedly when exposed to repeated stress, even if the initial stress is well below the material’s yield point. By conducting fatigue testing, they can gain a better understanding of how a material will behave under real-world conditions and design more durable and reliable products.

Fatigue testing standards provide a set of guidelines for conducting and evaluating the results of fatigue tests on materials and components. Two of the most widely used standards for fatigue testing are those developed by ASTM International and the European Committee for Standardization (CEN).

There are several widely used standards for fatigue testing, including:

- ASTM E466 – Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests on Metallic Materials

- ASTM E606 – Standard Practice for Strain-Controlled Fatigue Testing

- ASTM E647 – Standard Test Method for Measurement of Fatigue Crack Growth Rates

- ASTM E1012 – Standard Practice for Verification of Testing Machine

- ASTM E1823 – Standard Terminology Relating to Fatigue and Fracture Testing

- ISO 1099-2 – Metallic Materials – Fatigue Testing – Axial Force-Controlled Method

- ISO 12106 – Metallic Materials – Fatigue Testing – Rotating Bending Fatigue Test Method

- EN 12952 – Fatigue testing of welded joints

Standards for Fatigue Testing of Thermoset Composites

ASTM D3479 and ASTM D7291 are two widely used standards for fatigue testing of thermoset composites.

ASTM D3479 covers the standard test method for tension-tension fatigue of polymer matrix composite materials, while ASTM D7291 covers the tension-tension fatigue testing of polymer matrix composite materials using a cruciform specimen.

Both standards provide guidelines for testing the fatigue behavior of thermoset composites under cyclic loading conditions. They provide specific requirements for sample preparation, test setup, and data analysis, as well as recommended procedures for determining the fatigue properties of the material, such as fatigue life, fatigue strength, and stiffness.

By using these standards, the fatigue performance of thermoset composites can be evaluated and compared across different materials and test conditions, helping to ensure their safe and reliable use in structural and load-bearing applications.

Types of fatigue testing

Axial loading

- Uniform stress or strain is directly applied to the cross section of the specimen in tension or compression

- The specimen is held at both ends and loaded cyclicaly between minimum and maximum values

- During repeated bending, one end of the specimen is fixed while a stress or strain is applied to the other end such that the specimen bends in the same plane.

Rotating Bending Fatigue

- The specimen is revolved at constant frequency while a load is applied at two clamping points on either side of the specimen.

- In every rotationally cycle, the stresses change from compressive to tensile and from tensile to compressive

Torsion Fatigue

Each end of the specimen is clamped or twisted to predetermined values via tension or strain.

Daily Life Examples of Fatigue Testing

here are some examples where fatigue testing may be indirectly relevant in everyday life:

- Testing the durability of various materials used in automobiles, such as engine components, suspension systems, and tires, to ensure they can withstand the repetitive stresses and strains of daily driving.

- Evaluating the long-term performance of sporting equipment, such as tennis rackets, golf clubs, and bicycles, to ensure they can withstand repeated use and loading over time.

- Assessing the durability and fatigue life of consumer products, such as smartphones, laptops, and other electronic devices, to ensure they can withstand repeated use and handling.

- Testing the strength and fatigue resistance of building materials, such as concrete, steel, and wood, to ensure they can withstand the stresses and strains of daily use and environmental conditions.

Summary

Here are some key summary points of fatigue testing of thermoset composites:

- Fatigue testing of thermoset composites is important for evaluating their performance and durability under cyclic loading conditions.

- Two widely used standards for fatigue testing of thermoset composites are ASTM D3479 and ASTM D7291.

- These standards provide guidelines for sample preparation, test setup, and data analysis, as well as recommended procedures for determining fatigue properties such as fatigue life and strength.

- The fatigue performance of thermoset composites can be accurately evaluated and compared by following these standards.

- Fatigue testing can help ensure the safe and reliable use of thermoset composites in various structural and load-bearing applications.

More Interesting Links

Can Force be Negative?| Easy Explanation

Flexural Strength- An Overview

Is Titanium Magnetic?

Mechanical Energy Formula & Examples

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023