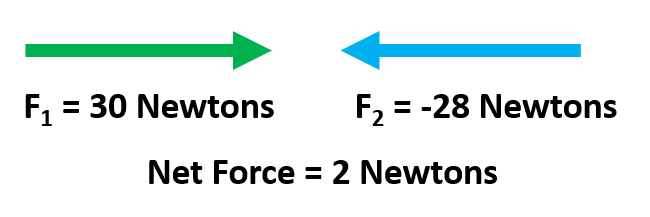

Engineering stress is the force applied to an object divided by its original area, while true stress is the force applied to an object divided by its actual area. The difference is that engineering stress assumes that the area remains constant, whereas true stress takes into account the change in an area that occurs as a result of the force applied.

For instance, Imagine you have a rubber band that is one centimetre wide and you pull it with a force of 1 Newton. The engineering stress would be the force (1 N) divided by the original area (1 cm), which equals 1 N/cm. However, as you continue to pull the rubber band, it stretches and becomes thinner, so the actual area that the force is applied to is now smaller than the original area. This means that the true stress is actually higher than the engineering stress because it takes into account the change in the area.

Table of Contents

The formula of Engineering Stress and True Stress

| # | Stress or Strain | Formula | Example |

| 1 | Engineering stress | Stress = Force / Area | If a force of 100 N is applied to a bar with a cross-sectional area of 10 cm^2, the engineering stress is 10 N/cm^2. |

| 2 | True stress | Stress = Force / Actual Area | If a force of 100 N is applied to a bar that elongates and has an actual cross-sectional area of 8 cm^2, the true stress is 12.5 N/cm^2. |

| 3 | Engineering strain | Strain = Change in length / Original length | If a 10 cm long bar stretches to 12 cm under a tensile force, the engineering strain is (12 cm – 10 cm) / 10 cm = 0.2. |

| 4 | True strain | Strain = ln(1 + Engineering strain) | If the engineering strain is 0.2, the true strain is ln(1 + 0.2) = 0.182. |

Difference between Engineering Stress and True Stress

| Engineering Stress | True Stress | |

| Definition | Engineering stress is defined as the applied force divided by the original cross-sectional area of the material. | It takes into account the changes in the material’s dimensions as it is stressed. It is a more accurate measure of stress experienced by a material, particularly when the material is undergoing plastic deformation. |

| Assumption | Engineering stress is related to engineering strain via Hooke’s law, σ ≈ Eε, where σ is the engineering stress, E is Young’s modulus, and ε is the engineering strain. | True stress is defined as the applied force divided by the actual cross-sectional area of the material at any given point during the deformation process. |

| Accuracy | It is less accurate at high levels of deformation. | It is more accurate at high levels of deformation. |

| Relationship | True stress is related to true strain via a material-dependent coefficient, σₜᵣᵤₑ ≈ Kε, where σₜᵣᵤₑ is the true stress, K is the true stress-strain coefficient, ε is the true strain. | σₜᵣᵤₑ = F / Aₜ, where σₜᵣᵤₑ is the true stress, F is the applied force, and Aₜ is the actual cross-sectional area of the material at any given point during deformation. |

| Examples | Examples of engineering stress include Young’s modulus and tensile tests on metals and alloys. | Examples of true stress include true stress-strain curves for materials undergoing large amounts of plastic deformation, such as polymers or ductile metals. |

| Formula | σ = F / A₀, where σ is the engineering stress, F is the applied force, and A₀ is the original cross-sectional area. | σₜᵣᵤₑ = F / Aₜ, where σₜᵣᵤₑ is the true stress, F is the applied force, and Aₜ is the actual cross-sectional area of the material at any given point in time during deformation. |

Daily Life Examples of Engineering Stress and True Stress

- Engineering stress: When you stretch a rubber band, the force you apply is divided by the original cross-sectional area of the band, giving you engineering stress.

- True stress: When you continue to stretch the rubber band, it becomes thinner, so the actual area that the force is applied to decreases. To calculate the true stress, you need to divide the force by the actual area of the band, which takes into account the change in an area that occurs as the band stretches.

- Engineering stress: When you jump on a trampoline, the force you apply to the surface is divided by the original surface area of the trampoline, giving you engineering stress.

- True stress: However, as you jump on the trampoline, the surface stretches and becomes thinner, so the actual area that the force is applied to decreases. To calculate the true stress, you need to divide the force by the actual area of the trampoline, which takes into account the change in the area that occurs as the trampoline surface stretches.

More Links

Tensile Stress – Definition, Formula, SI Unit, and FAQs

Compressive Stress – Definition, Formula, SI Unit, and FAQs

Yield Point| Definition and Stress-Strain Relation

Elastic Limit| Definition, Formula, and Simple Explanation

Flexural Strength| Simple Definition and Daily Life Examples

Strain Energy- Definition, Formula and Daily Life Examples

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023