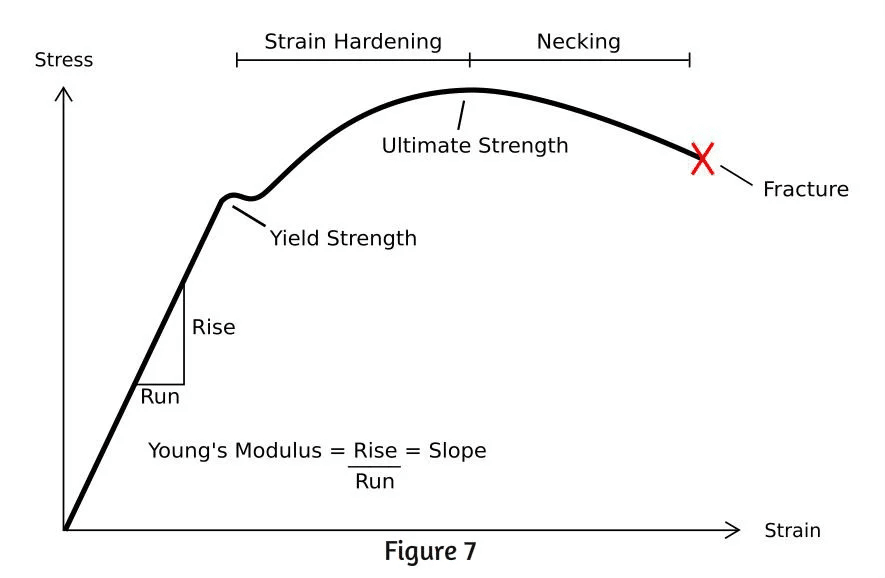

The fracture point is the point where a material breaks apart due to strain. It’s the moment when the strain on the material reaches its highest value, causing it to physically separate. This can happen even if the corresponding stress on the material is lower than its ultimate strength.

Ductile materials have a fracture strength that is lower than their ultimate tensile strength (UTS). When a ductile material reaches its UTS under a load, it will continue to deform without any additional load until it eventually breaks. However, if the material is subjected to displacement-controlled loading, the deformation of the material may relieve the load, preventing it from rupturing.

On the other hand, brittle materials have a fracture strength that is equivalent to their UTS. When a brittle material reaches its UTS, it fractures immediately without much deformation.

In simple terms, the fracture point is where a material breaks apart due to strain. Ductile materials can deform more before breaking, while brittle materials break with less deformation. The type of loading, whether it’s load-controlled or displacement-controlled, can also affect how the material behaves before breaking.

Table of Contents

Brittle and ductile fractures

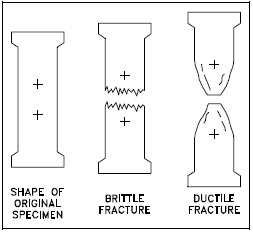

Brittle and ductile fractures are two different types of material failure that occur when a material is subjected to excessive stress or strain.

Brittle fracture: When a material experiences a brittle fracture, it breaks suddenly and without warning. Brittle materials lack significant plastic deformation before fracture, meaning they do not show much visible deformation or stretching before breaking. Instead, the fracture occurs along a clean and smooth surface. Examples of brittle materials include glass, ceramics, and cast iron. Brittle fractures typically happen when the applied stress exceeds the material’s strength, leading to rapid and catastrophic failure.

Ductile fracture: In contrast to brittle fracture, ductile fracture involves significant plastic deformation before the material eventually breaks. Ductile materials can stretch and undergo plastic deformation under stress, which allows them to absorb energy before ultimate failure. This deformation is visible in the form of necking or localized thinning of the material. Examples of ductile materials include most metals like steel and aluminum. Ductile fractures occur when the material undergoes significant deformation, and the stress exceeds its ultimate strength. The material gradually stretches and elongates until it reaches its breaking point.

In summary, brittle fracture is characterized by sudden and immediate failure without much visible deformation, while ductile fracture involves significant plastic deformation before eventual failure. The behavior of a material under stress depends on its inherent properties, such as its composition, microstructure, and temperature.

More Links

Yield Point| Definition and Stress-Strain Relation

Stress in Physics| Definition and Easy Examples

Tensile Stress – Definition, Formula, SI Unit, and FAQs

Bending Stress: The Good, The Bad, and The Bendy

Difference between Displacement and Distance

Fatigue Testing of Thermoset Composites

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023