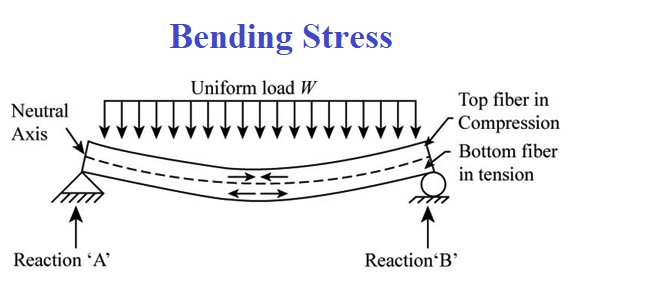

Bending stress is like when you try to bend a stick or a straw. The force you use to bend it creates stress inside the stick or straw, which resists the bending. The maximum stress happens on the side of the stick or straw that’s farthest from the middle, where it doesn’t bend. This stress can be important for things like buildings and bridges because we need to make sure they don’t bend or break too much under the weight of people and things on them.

Table of Contents

Daily Life Examples of Bending Stress

- Bending a plastic straw to drink a beverage.

- Bending a paper clip to hold papers together.

- Bending a key to unlock a door.

- Bending a tree branch to climb it.

- Bending a pencil or pen while writing.

- Bending a spoon or fork while eating.

- Bending a hanger to hang clothes.

- Bending a wire to make a craft or jewellery.

- Bending a credit card to fit into a wallet.

- Bending a cookie sheet to fit into an oven.

Bending Stress Formula

The formula for calculating bending stress is:

σ = (M * y) / I

where:

- σ is the bending stress in the material

- M is the bending moment acting on the section of material

- y is the distance from the neutral axis to the point where the bending stress is being calculated

- I is the second moment of area of the cross-sectional shape of the material.

The bending moment is a force that causes a material to bend, and it is calculated by multiplying the force applied by the distance from the force to the point where the bending occurs. The second moment of area is a property of the cross-sectional shape of the material, which describes how much the material resists bending in different directions.

Bending Strain

Bending strain is like when you bend a stick or a straw, and you can see how it stretches or compresses on the top and bottom. The amount that the stick or straw stretches or compresses is called bending strain. This bending strain is caused by the force that’s applied to the material and how much the material can stretch or compress without breaking. The formula for calculating bending strain is:

ε = (y * δ) / L

where:

- ε is the bending strain

- y is the distance from the neutral axis to the point where the bending strain is being calculated

- δ is the amount of deflection or displacement of the material at that point

- L is the length of the material being bent.

Bending Modulus

The bending modulus is like the strength of a material when you try to bend it. Imagine trying to bend a thin stick and a thick wooden plank. The thick plank will be harder to bend because it’s stiffer and stronger. The bending modulus measures how much a material can resist bending and stay straight.

The bending modulus formula is:

E = (M * L^3) / (4 * I * δ)

where:

- E is the bending modulus

- M is the bending moment acting on the material

- L is the span length or distance between the supports

- I is the second moment of area of the material’s cross-section

- δ is the deflection or bending of the material under the load.

Sample Problem: Step-by-Step Solution

Example: A wooden beam that is 2 meters long and has a cross-section of 10cm x 10cm is supported at both ends. A weight of 500 N is placed in the middle of the beam. What is the maximum bending stress in the beam?

Solution:

- Calculate the bending moment:

The bending moment is the force applied to the beam multiplied by the distance from the force to the point of support. In this case, the weight of 500 N is acting at the midpoint of the beam, which is 1 meter from each support. So, the bending moment can be calculated as:

M = F * d M = 500 N * 1 meter M = 500 Nm

- Calculate the second moment of area:

The second moment of area is a property of the beam’s cross-sectional shape that affects how much it resists bending. For a square cross-section, as in this example, the second moment of the area can be calculated as:

I = (b * h^3) / 12 I = (0.1 meter * (0.1 meter)^3) / 12 I = 0.00083333 meter^4

- Calculate the maximum bending stress:

The maximum bending stress occurs at the point farthest from the neutral axis, which is the line through the center of the beam that doesn’t bend. In this case, the maximum bending stress occurs at the bottom of the beam. The distance from the neutral axis to the bottom of the beam is half of the height or 0.05 meters. So, the maximum bending stress can be calculated as:

σ = (M * y) / I σ = (500 Nm * 0.05 meter) / 0.00083333 meter^4 σ = 30,000,000 Pa or 30 MPa

So, the maximum bending stress in the wooden beam is 30 megapascals.

Difference between bending and compression

The differences between bending and compression:

| Terms | Bending | Compression |

| Definition | Directed towards the centre of the material. | Material is pushed or squeezed, causing it to get shorter or smaller in volume. |

| Stress | Different on the top and bottom of the material. | The same all around the material. |

| Force | Directed perpendicular to the length of the material. | Directed towards the center of the material. |

| Example | Walking across a bridge. | Sitting on a chair. |

Advantages and Disadvantages of Bending Stress

| # | Advantages | Disadvantages |

| 1 | Flexibility: Bending stress allows materials to be flexible and conform to different shapes and sizes, making them useful in a variety of applications. | Brittle materials: Brittle materials such as ceramics can fracture easily when subjected to bending stress, making them unsuitable for many applications. |

| 2 | Strength: Materials that are designed to resist bending stress can be made to be very strong and durable, making them suitable for use in structures that need to withstand heavy loads. | Fatigue failure: Repeated or prolonged exposure to bending stress can lead to fatigue failure, where a material fails due to small cracks that form over time. |

| 3 | Control: Bending stress can be precisely controlled, allowing engineers to design structures with specific shapes and properties. | Design complexity: Designing structures to withstand bending stress can be complex and challenging, requiring careful consideration of factors such as the material properties, load distribution, and support conditions. |

More Links

Resilience: Examples from Physics and Everyday Life

What Is Malleability in Metal?

Yield Point| Definition and Stress-Strain Relation

Stress in Physics| Definition and Easy Examples

Elastic Limit| Definition, Formula, and Simple Explanation

The Spring Constant & Spring Force Concept

Joke of the day

Why did the material scientist break up with the stress analyst? Because they couldn’t handle the strain in their relationship!

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023