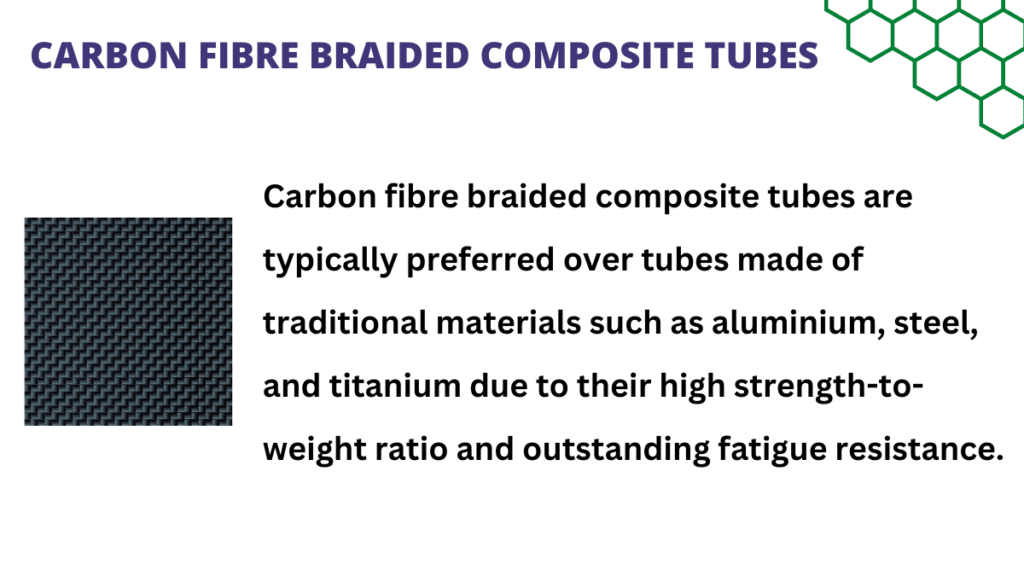

Carbon fibre braided tube consists of interwoven yarns embedded in a resin system. Tubular braided composites are being utilized in a number of applications, including biomedical, sports, aerospace, and military, due to their high strength-to-weight ratio and performance under 3-D stress states.

Table of Contents

Carbon Fiber Tube

Carbon fibre braided composite tubes, as compared to laminated composites, provide higher impact resistance and the ability to create near-net-shape preforms. Some of the key points are listed below:

- Carbon fibre braided tubes have been proven in recent research to be ideal candidates for space application constructions due to their high specific stiffness, thermal stability, and fatigue resistance.

- Fibre strands/tows are interwoven in clockwise and counterclockwise orientations around a tubular mandrel in biaxial tube braiding, resulting in a bidirectional helically interlaced structure.

- The braid (or braiding) angle is the helix angle with respect to the tube axis, with theoretical values ranging from 0o to 90o.

- A tow oriented axially and not wrapped around the component has a braid angle of 0o.

- A tow that wraps around the structure but does not proceed along the main axis has a braid angle of 90o.

How to Make Carbon Fiber Tubes

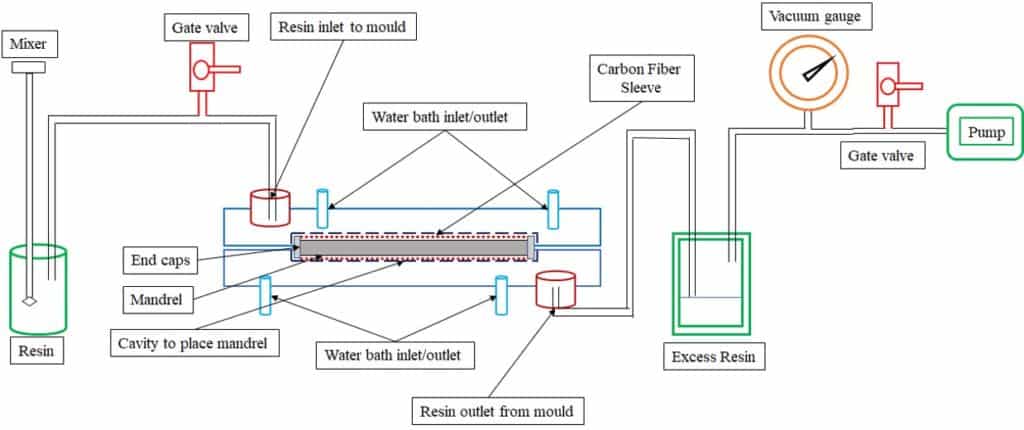

These tubes can be prepared by Vacuum Assisted Resin Transfer Molding (VARTM) with the following steps:

- To make demolding easier, the Easy-Lease release agent is applied to the mandrel and mould cavity.

- Depending on the pattern, layers of braided sleeves are pulled over the mandrel.

- The mould is clamped shut after the mandrel is wrapped in braided sleeves and put in the cavity.

- The resin is warmed to 40 degrees Fahrenheit and then degassed. Following that, the mould is subjected to a vacuum pressure of -1 bar, causing the resin to infuse into the mould. The injection takes ten minutes to complete.

More Interesting Topics

Latest posts by Umair Javaid, PhD Student (see all)

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023