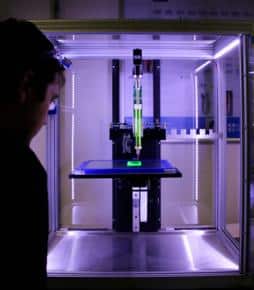

Additive manufacturing (3D printing) is a technique where 3D solid objects are created by adding material layer by layer. This technique allows us to create physical 3D dimensional objects directly from a computer design.

Keep reading to know more about the definition, working, and applications of 3D printing.

Table of Contents

Additive Manufacturing

Additive manufacturing is defined as a process that allows you to create physical 3D dimensional objects directly from a computer design. It allows you to innovate quickly, instead of moulding a part or machining it, this technique involves technology that fuses the material and deposits it to the plate at the rate of the single minute layer at the time.

It makes it possible to customize a part, changing the details at the last minute because there is no dedicated mould tooling.

This technique can eliminate a lot of assembly work because a part that might be assembled from a lot of smaller components could be grown as a single piece instead.

How Does Additive Manufacturing Work?

- The first step is to create a sketch of the required object.

- You can use modeling software like Blender to create your own designs or you can visit websites like Thingiverse and Shapeways to find objects other users have 3D modeled.

- Once you have finished the design, it’s time to send it to the printer. Some modern printers like MAKERBOT REPLICATOR 2X have removable string-like bioplastics spools in the back of the device.

- When the printer receives the design, it pulls the material through the tube, melts it, and deposits it to the plate, where it instantly cools.

- The most common material used in 3D printing is plastic, but some other materials allow for the creation of complex products beyond simple tools and toys.

What is 3D printing used for?

Speaking of design, 3D printing paves the way for incredibly customized objects, made of demand to fit requirements. Not only does this mean furniture, shoes and appliances built to fit your lifestyle, but things like prosthetic limbs can have completely customized user designs, as opposed to generic mass-produced products.

Typical 3D printers create layers approximately 100 micrometres thick, but some high-end machines can print as small as 16 micrometres. To put this in perspective, a typical bacteria cell has a width of between 1 to 10 micrometres. This has open the doors of using molecules for ink and has led to successful 3D printed pharmaceutical drugs, such as Ibuprofen. The tiny molecules are organized perfectly to create the desired drug effect.

3D printing produces a variety of end-use production parts. Some of interesting examples are listed below:

- Engineers are using 3D printing to make parts of jet engines that are lighter and stronger to make aeroplanes more efficient and use less fuel.

- smaller consumer-friendly 3D printers are bringing additive manufacturing to home and businesses.

- Engineers are using 3D printing to make parts of jet engines that are lighter and stronger to make airplanes more efficient and use less fuel.

- Smaller consumer-friendly 3D printers are bringing additive manufacturing to homes and businesses.

- 3D printed small body parts like ears and noses are being widely used nowadays.

- Recently, giant 3D printers in China printed ten houses in just one day at a cost of approximately 5000 $ per home, proving just how cost and time-efficient 3D printing can be.

Related Topics

What Is Artificial Intelligence (2020 Trends)

STEM Education

Frequently Asked Questions (FAQs)

1. What is sublimation printing?

Sublimation printing is an easy process for printing high-quality images on mugs, cell phone cases, tiles, trophies, and apparel.

The CAD design is printed using a special printer.

The printed image is placed on the surface to be sublimated, between the top and bottom place of the heat press. Pressure and heat are applied to turn the printed image into gas.

The ink penetrates the pores of the substrate. After that, the ink gets solidified and creates a permanent image on the product.

2. What is Additive Manufacturing Principle?

Much like 2D printers print ink on a page, 3D printers spit out materials, whether it be plastic, metal, or even concrete to form a three-dimensional object. But instead of printing one layer, as ink from a normal printer does, multiple layers are stacked upon each other to create complex 3D structures.

Bottom Line

This article explains the basics of the 3D printing (additive manufacturing) technique. We hope after reading this article you are able to understand the importance of 3D printing in the modern world. If you have any question or thought, please feel free to comment or send an email to [email protected]

- BCl3 Lewis Structure in four simple steps - November 1, 2023

- PH3 Lewis Structure in four simple steps - October 8, 2023

- PF3 Lewis structure in four simple steps - September 24, 2023